Deskripsi Produk

As optical communication era is coming, components production of optical communication change from lab or small scale production style to mass production style, original cost reduces also. Laser processing technology plays a important role during this period. So far, laser welding, laser dicing, percing and engraving technology are very mature, especially for laser welding technology.

The pricinple of laser welding is using high power laser to melt surface material and make them weld together. It is non-contact welding, no outer force which will cause stress and deformation. Welding time is in millisecond, heating effect area is only within beam focusing area, with high processing efficiency and suitable for mass production.

| Model | HW-500 | HW-1000 | HW-1500 | HW-2000 |

| Maximum laser power | 500 | 1000 | 1500 | 2000 |

| Frekuensi laser | 50-5000HZ | 50-5000HZ | 50-5000HZ | 50-5000HZ |

| Power adjustment range | 10-100% | 10-100% | 10-100% | 10-100% |

| Power instability | <3% | <3% | <3% | <3% |

| Welding penetration (stainless steel) | 1.2mm | 2.0mm | 2.5mm | 3.0mm |

| Welding penetration (carbon steel) | 0.8mm | 1.5mm | 2.5mm | 3.0mm |

| Welding penetration (aluminum steel) | 1mm | 2mm | 3mm | 4mm |

| Swing welding spot | Solder spot 2-4mm | Solder spot 2-4mm | Solder spot 2-4mm | Solder spot 2-4mm |

| Input voltage | 220V/50HZ | 220V/50HZ | 380V / 50HZ | 380V / 50HZ |

| Total power | ≤3KW | ≤3KW | ≤3KW | ≤3KW |

| Automatic wire feeding | Optiona | Pilihan | Optiona | Pilihan |

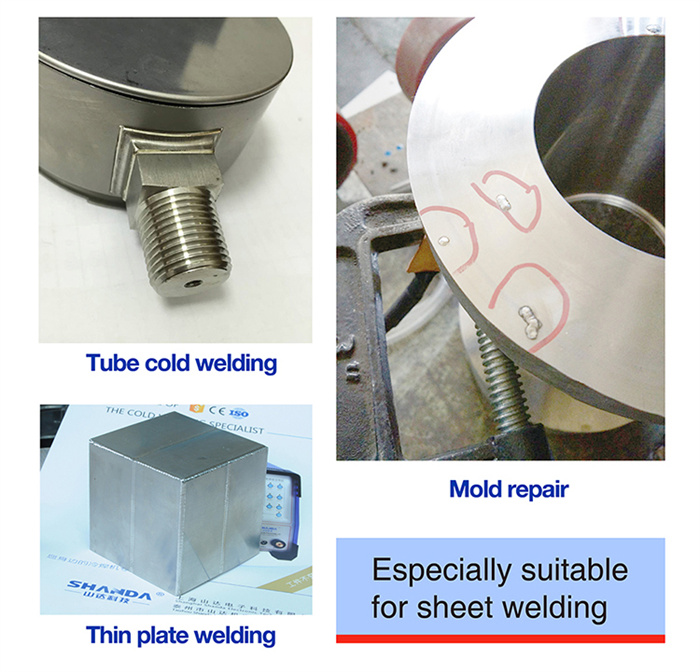

Application field

Mesin las laser banyak digunakan di industri kamar mandi, industri otomotif, industri perangkat keras, industri medis, dll.

Bagian mesin

wire feeder

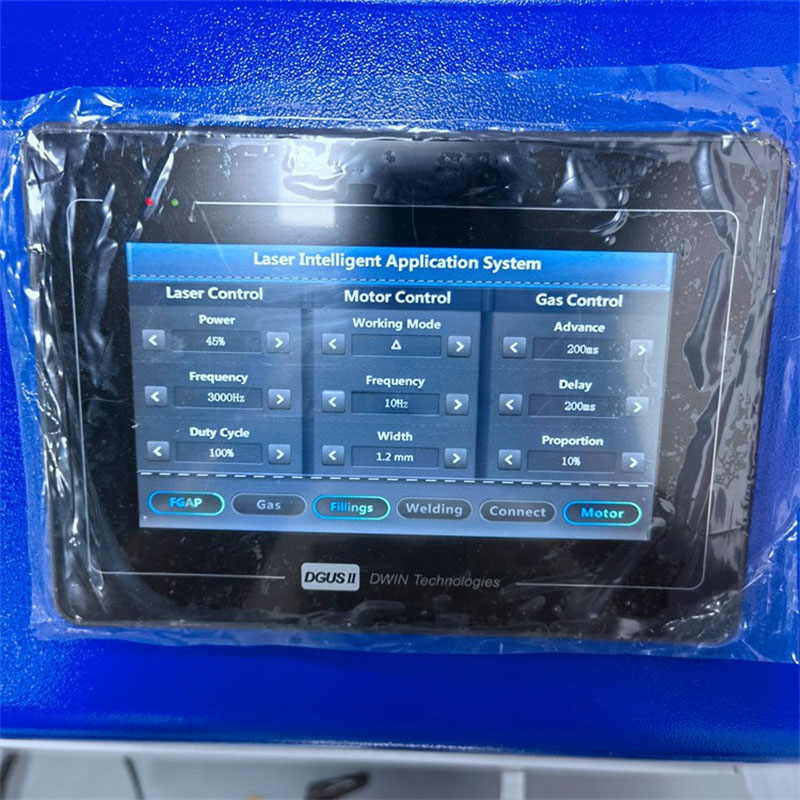

control system

water chiller

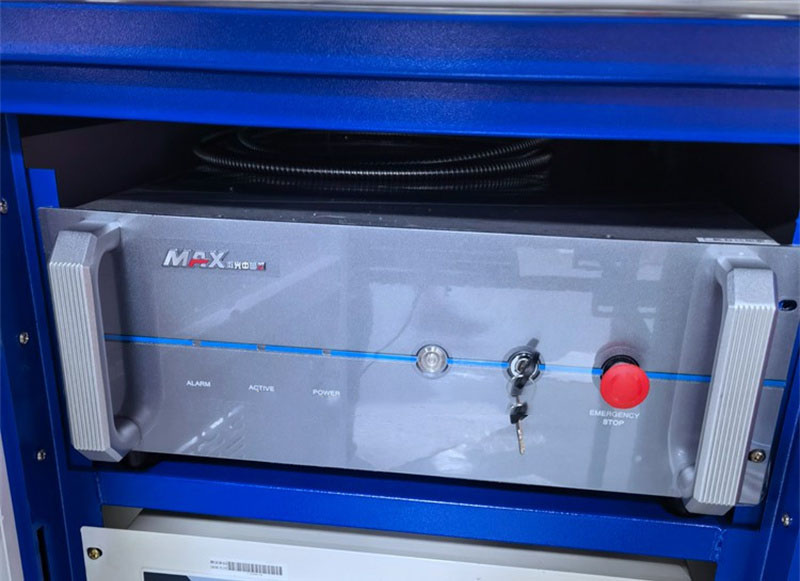

laser generator

laser welding head

nk

Advantages

FINE WORKMANSHIP

It is suitable for various complicated welding seams and spot welding of various devices. Mainly for the welding of thin metal sheets within 0.5 ~ 3.0 mm which makes up for the trouble of traditional argon arc welding technology for hot-melting, easy deformation and further processing after welding

GOOD STABILITY

Pure and stable fiber laser source, maintenance free

Excellent Welding effect, With continuous emission laser mode so welding spot is even and welding surface is very smooth and clean,no need the second process after welding Easy operation and save you expensive technical labor costs

NO any consumable parts , Maintenance free

VARIOUS SPECIFICATIONS

A variety of hand-held nozzles are available which can be selected for various requirements such as metal parts, internal welding, right-angle welding narrow-side welding, and large spot welding

EFFICIENT WORK

High Efficiency This product breaks through the traditional practice and adopts directional point-to-point welding, which is 10- 15 times faster than ordinary welding and has high work efficiency